Materials

Stainless Steel

Our experts have extensive experience working with 304SSL and 316SSL, known for their exceptional durability and versatility. Skilled in manufacturing components for industries such as food processing, pharmaceuticals, marine, and architecture. Expertise in precision cutting, forming, welding, and finishing stainless steel to meet diverse application needs.

Aluminum

Our experts have extensive experience working with various aluminum grades, including 5052, 5083, and 6061. Skilled in lightweight fabrication for industries such as aerospace, automotive, construction, and electronics. Expertise in cutting, forming, welding, and finishing aluminum with precision and efficiency.

Nickel Alloy

Our experts have extensive experience working with high-performance nickel alloys like C276, AL6XN, Inconel 625, and 904L. Skilled in fabricating components for demanding industries such as chemical processing, marine, aerospace, and power generation. Advanced capabilities in cutting, forming, welding, and machining nickel alloys to precise tolerances.

Duplex Alloy

Our experts have extensive experience fabricating duplex alloys such as 2205, 2507, and LDX for high-performance applications. Expertise in cutting, forming, welding, and machining duplex alloys to meet industry-specific demands. Trusted partner for industries like chemical processing, oil and gas, marine, and pulp and paper.

Carbon Steel

While not a primary focus of our business, we have the capabilities to work with carbon steel for specific projects. Experience in cutting, forming, welding, and machining various grades of carbon steel. Able to deliver quality components for structural, industrial, and general-purpose applications.

Featured Project

Material selection is fundamental to performance, durability, and long-term system efficiency. At D&R Custom Steel, we work with a broad range of metals including stainless steel, carbon steel, aluminum, and high nickel alloys such as C276 and AL6XN. Each material is chosen to suit the environmental, structural, and operational requirements of every project.

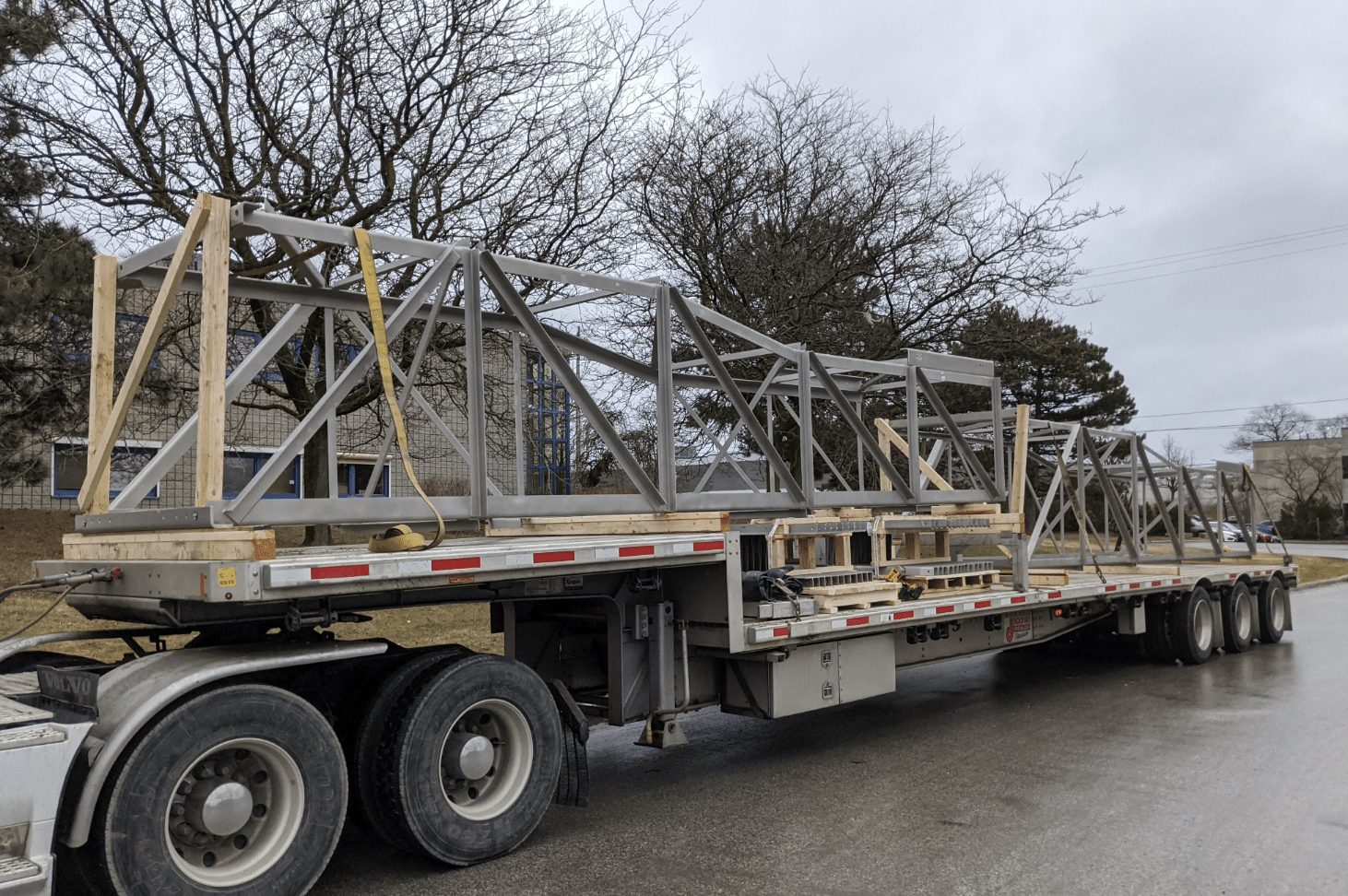

Featured Project: Two 146’ Clarifiers – Calgary, AB

This project involved the fabrication and delivery of two 146-foot clarifiers using 316 stainless steel and 6061-T6 aluminum. The multi-material approach was essential to meet both structural and corrosion performance goals. The complexity of this build required careful coordination of machining, welding, and transport logistics resulting in a 12-truckload shipment executed on time and to spec.